BE ON TARGET.

Boresight Reimagined

The problem

All firearms with scopes require calibration to ensure that the firearm and scope are aimed at the same point. This process is called boresight. Current methods of boresighting do not collect data on calibration settings so a user can recall zero at a different point in time.

The solution

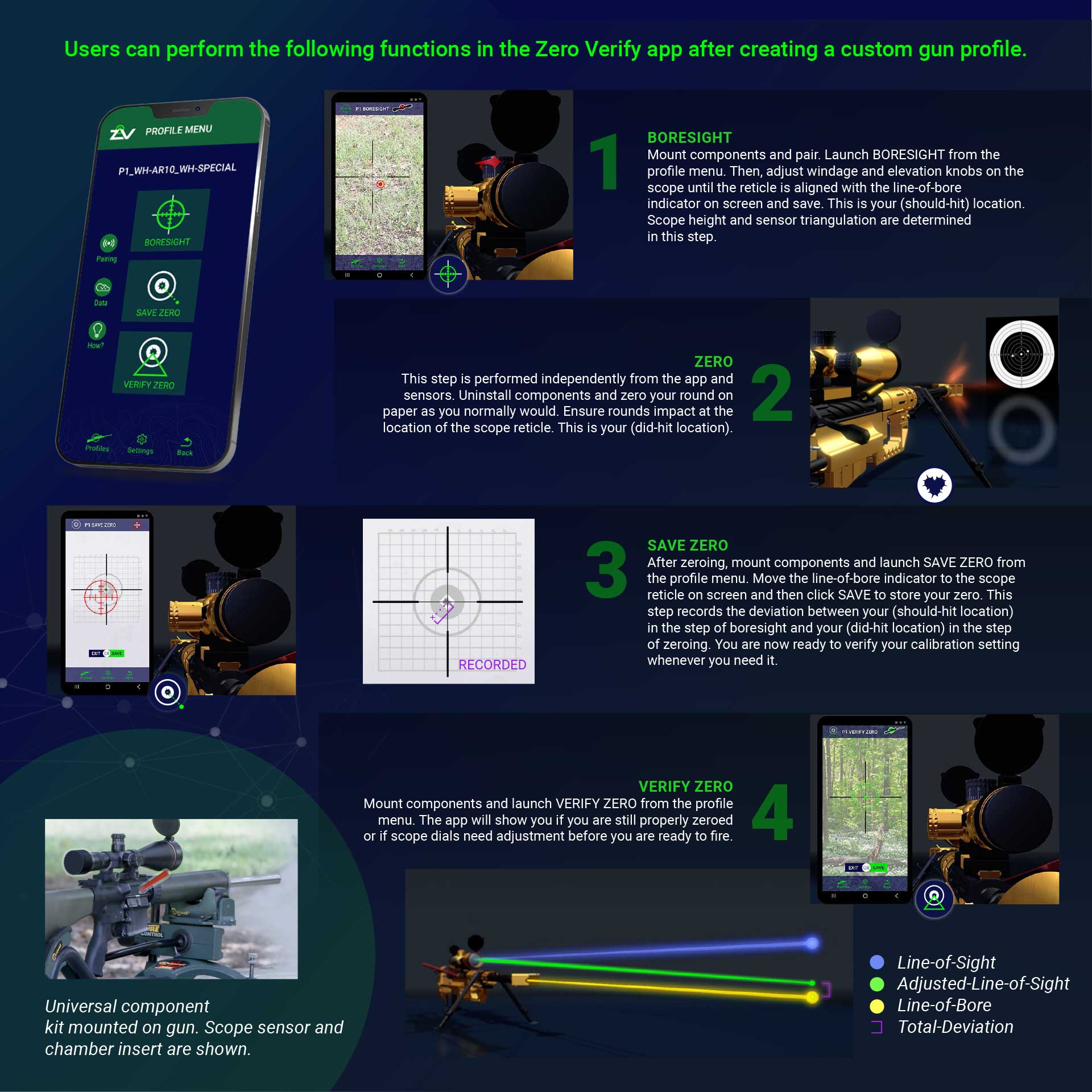

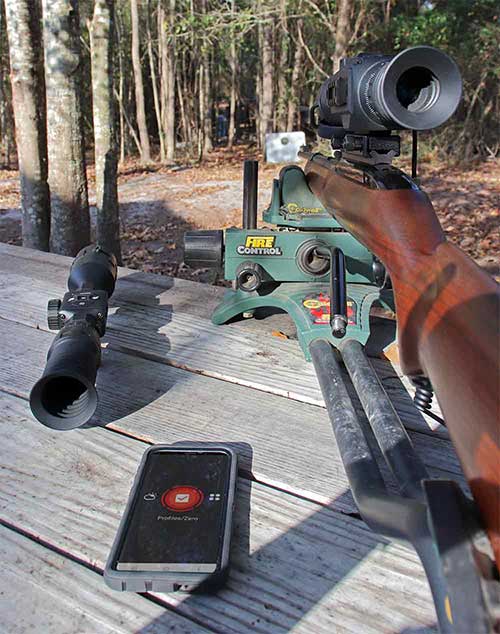

The Zero Verify app and sensor components will allow users to perform boresight and store critical calibration settings after initially zeroing a firearm. Calibration settings, ballistic input, and even ambient environmental data can be collected for a single gun profile for later recall. Users can then verify their firearm is zeroed in a new location without firing a live round. All boresighting devices reference the chamber as the departure point for a projectile but none mark the actual physical location with a sensor or beacon. This will make Zero Verify’s sensor system with scope to chamber detection unique to the field.

Research and Development

The following depictions of the app and sensors represent both functionality and marketing approach and do not constitute a final product. We are looking for assistance with sensor development, simulation tests, and application development.

Create profiles of your favorite guns

and verify calibration anywhere.

Patent # 9,335,125 Universal Firearm Marksmanship System

Patent # 10,145,653 Universal Firearm Marksmanship System

Patent # 10,739,109 Firearm Marksmanship System with Chamber Insert

Patent # 10,900,749 Universal Firearm Marksmanship System

Patent # 11002512 Firearm Marksmanship System with Chamber Insert

The App

Boresighting:

Increased accuracy over traditional boresight devices such as collimators and lasers prior to zeroing

Save Zero:

After zeroing the rifle, the calibration setting can then be stored for verification

When to Verify a Profile:

Anytime a sighting system has been compromised or knocked out of alignment

A new location where weather conditions and/or elevation have changed

Applications

Reinforces boresight procedures before going to zero range or qualification range and during lulls in mission.

Use before hunting expeditions, competition matches or trips to the range. Check and verify calibration.

Gives users confidence in sight setting and verification before patrol.

Where is the market now?

Mainstream optical collimators and laser boresighters have been around a long while and have not been substantially improved since the mid-’90s. These devices can get your first round on paper when zeroing — a far cry from accuracy. They require a known distance, good lighting, and may require a gun rest. Recalibration of a compromised scope can take up to sixty minutes to rezero or reset based on a sketch or measurement of the last sight setting.

Like most things, you get what you pay for. Increased accuracy comes with a hefty price tag. Many low-end common boresighters retail for around $30 to $60 while high-level precision instrumentation can retail well out of reach of the average sporting enthusiast. Red-i-Laser makes one of the best laser boresights in the industry. It is marketed as the “fastest, easiest, and most precise laser boresight in the world,” and sells with a price tag set just under $300. Even better yet, Pyser optics makes weapons collimators currently deployed in several NATO armed forces. They are used for quickly zeroing a firearm with no live firing and eliminate the need to zero at 25 yards on paper. They have a high level of accuracy of .25 mils or within 1 MOA at 100 yards. They are priced well over $1,000 and do not offer the same versatility of use with most firearms and sighting systems.

Conversely, the field of optics is changing almost exponentially. There are electro-optic sensing scopes on the market that attempt to mimic traditional boresight equipment by coupling app software, ballistic engines, rangefinders, and other devices to determine holdover location. ATN is a great example. Their sighting systems allow for one-shot zeroing compensation and also account for bullet drop factor based on an approximate distance to a given target. The ATN Obsidian 4 app is connected to the scope via device wifi and users can view the app settings directly through the scope. This type of technology is formidable in the field especially paired with an ATN rangefinder. Also of note, is Sig Sauer’s BDX scope and rangefinder combos fueled by Applied Ballistics Ultralight, a top-tier ballistic engine that other top optics brands use. Devices like Kestrel’s weather meters can be paired and further inform hold-over-location. Although the barrier to entry is going down, these optics can be cumbersome when firing rounds but are a great add-on to an experienced long-range shooter’s toolbox.

The military is also looking for new technology that boosts fire-control systems and calculates a projectile path to a given target. Top optics firms like Vortex, Leupold and Stevens, and L3 Harris are building optic prototypes for the Next Generation Squad Weapon program. These new optics will combine rangefinding capabilities, ballistic computation, and environmental sensors that increase accuracy and decrease the time it takes to engage. While advanced optics are not a necessity for civilian use, properly zeroing any firearm is a necessity for accuracy.

Regardless of the sophistication of the optic, a scope alone does not physically reference the firearm chamber location to determine sight adjustment.

All boresighting devices reference the chamber as the departure point for a projectile but none mark the actual physical location with a sensor or beacon. This will make Zero Verify’s sensor system with scope to chamber detection unique to the field — and the concept is patented.

There is no technology currently on the market that cross-references both the steps of boresighting and the steps of zeroing to save a profile for later recall. The ability to use Zero Verify with any scope and magnification level will be an advantage over electro-optic scopes in the future. Sportsmen who own an assortment of scopes may not be interested in purchasing the latest-greatest optic out there but may well be interested in ballistic engines and building their own personalized datasets for guns they own.

Zero Verify has the potential to do all of this, putting the scientific method in your back pocket and doing the guesswork for you — all with an affordable price tag and the versatility you can count on.

Traditional Methods of Boresighting

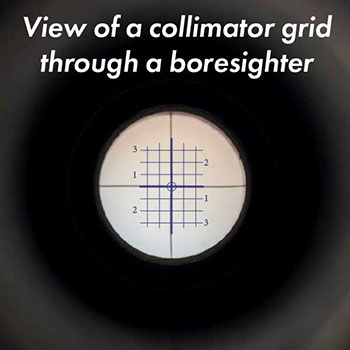

How to use a collimator boresight

Place or insert optical boresight at the muzzle end of a firearm making sure the center of the lens and boresight align. Look through the scope and adjust the elevation and windage knobs until the reticle and collimator grid are in alignment.

How to use a laser boresight

The laser is inserted into the barrel of the firearm and a laser light is beamed onto the target showing the line of bore. Elevation and windage can then be adjusted so that the reticle overlaps the laser beam before zeroing.